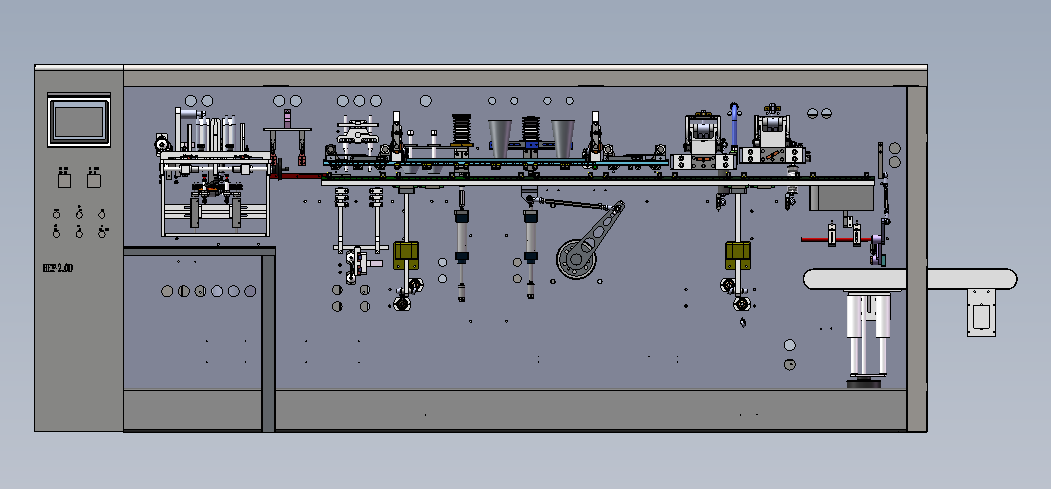

About Boevan Premade Pouch Packing machine BHP-210D

BHP Boevan Horizontal Premade Pouch Packing Machine Series offer flexible and economical solution for flat and doypack packing. The packing machine can pack powder, granule, liquid and tablet.

The BHP-210D packing machine’s filling capacity is 400ml, and the packing speed is about 80-100ppm, the maximum pouch width range that the packing machine can make is 75-105mm, the maximum pouch length range that the packing machine can make is 110-300mm.

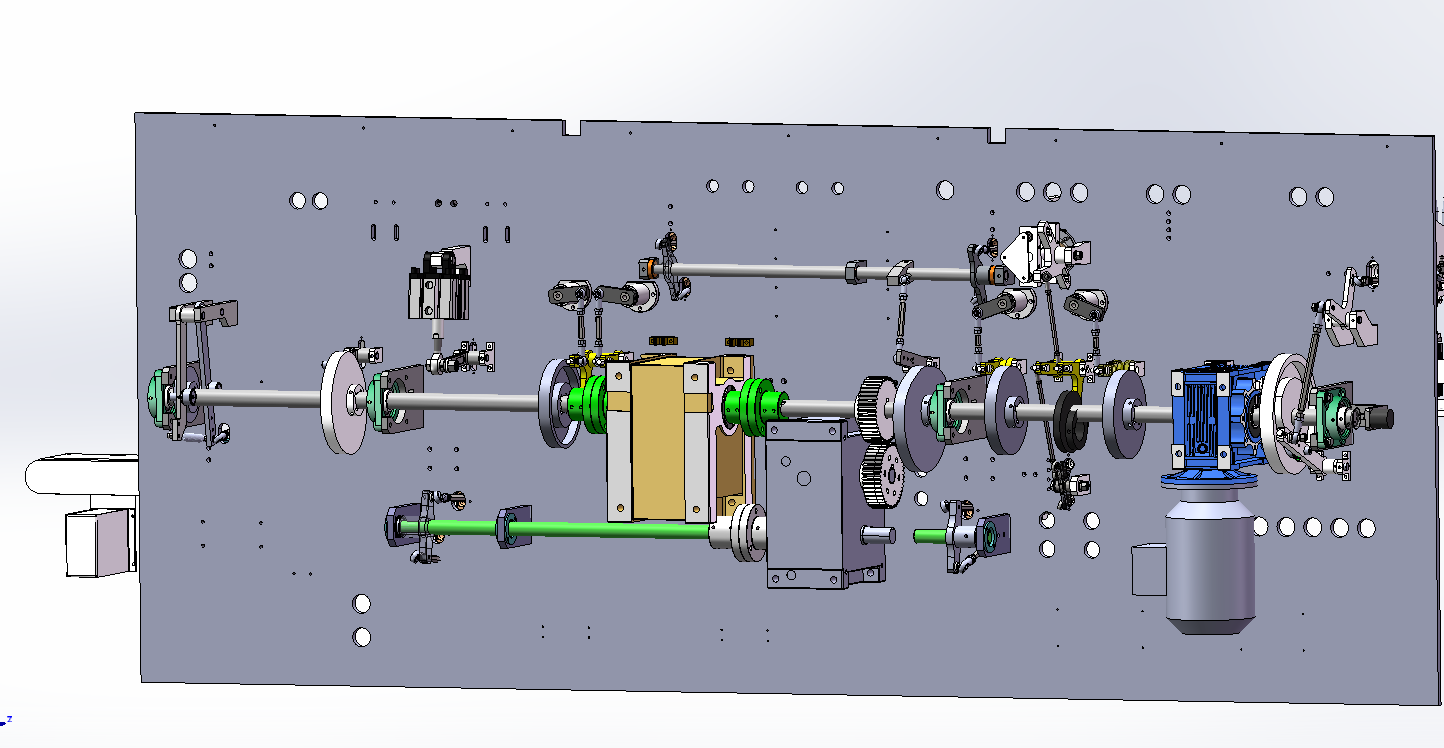

The premade pouch packaging machine has been optimized many times,The frame has been improved from the original pure sheet metal splicing to the current integrated baseboard internal frame splicing, which increases the overall reinforcement and stability of the equipment and reduces noise and resonance during operation.

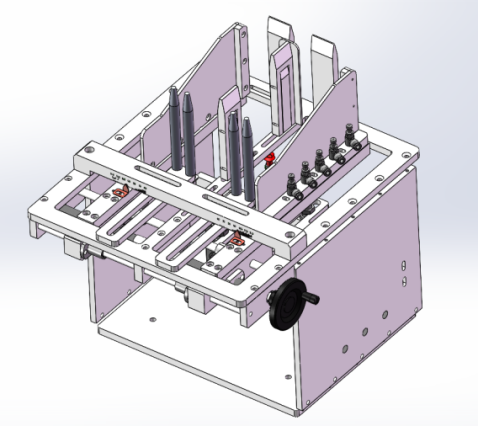

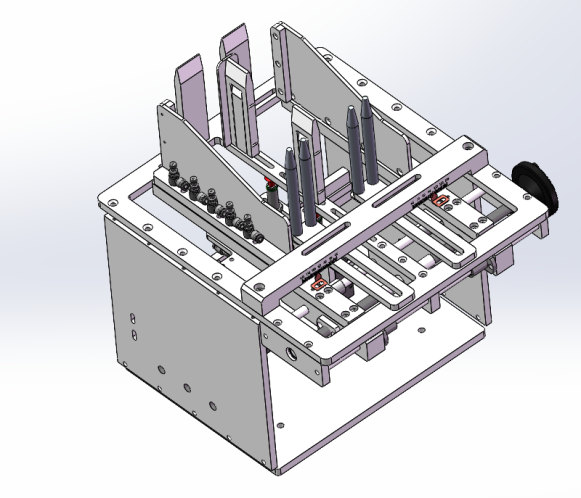

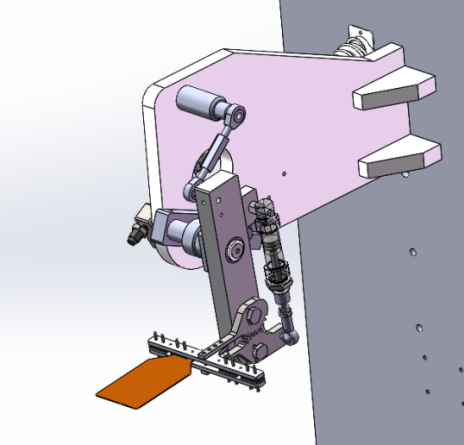

Bag storage bin improvements:The main structure is optimized and the thickness of parts is increased to avoid vibration when the equipment is running, and a screw adjustment device is added to make the operation more convenient and quick.

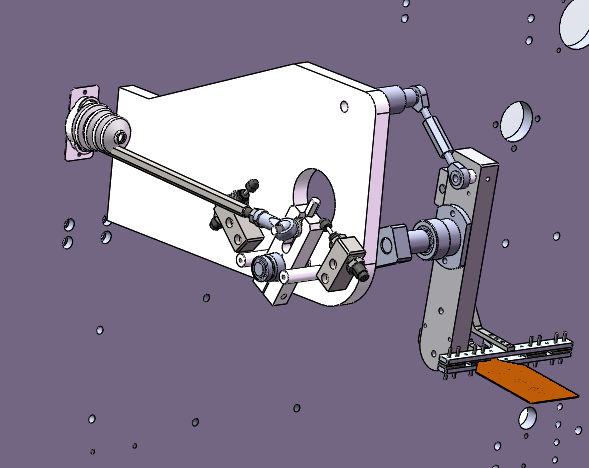

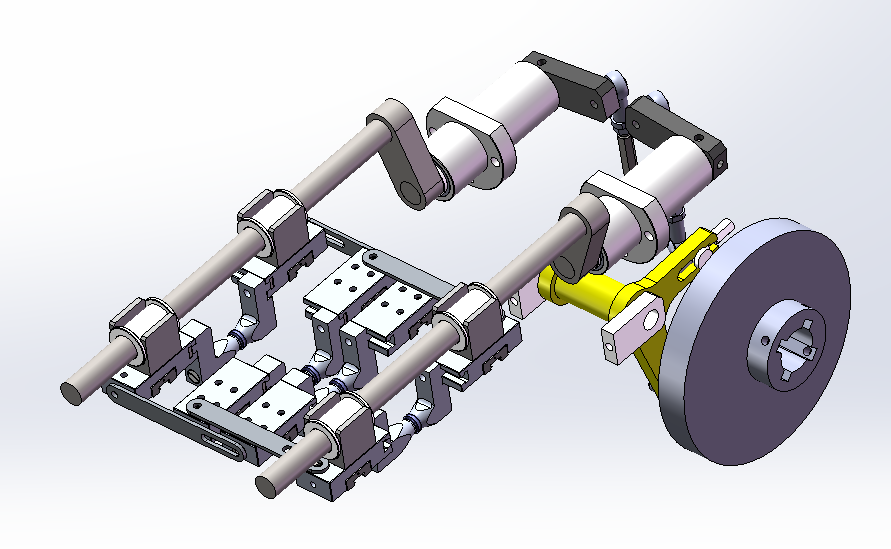

Improvements to bag taking robot:The drive structure is redesigned and optimized to make it more stable and vibration-free during operation.

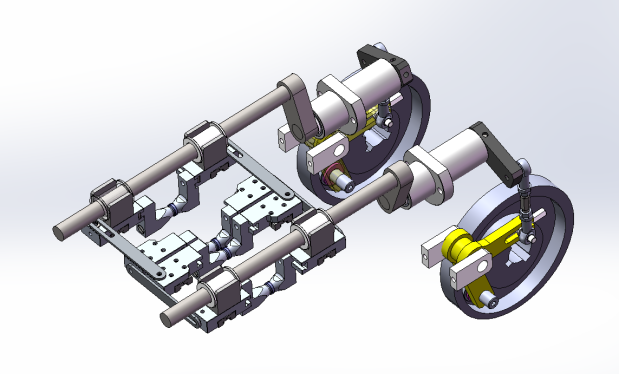

Bag opening improvement: A. Replace the original linear bearing with a linear guide rail to increase structural stability and improve the success rate of bag opening.

B.Increase the number of vacuum solenoid valves and increase the volume of vacuum gas storage tanks to ensure the stability of negative pressure when opening bags and improve the success rate of bag opening.

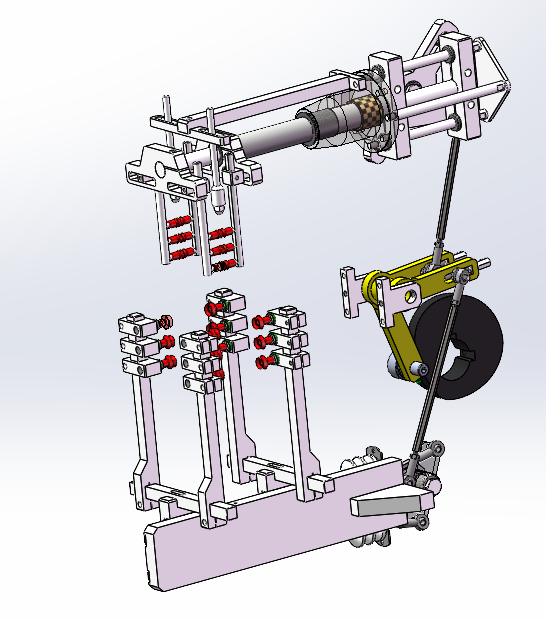

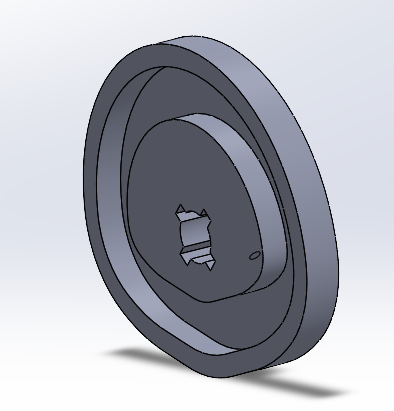

Car Improvement:A. The trolley conveying and lower trolley opening and closing driving functions have been improved from the original cam to the current cam divider driving function, making the bag conveying more stable.

Improved display bag:Optimize the bag opening structure and reduce the assembly gap, so that it can work more smoothly and accurately when assisting in bag opening and flattening the bag mouth, thereby improving the bag opening success rate and the sealing aesthetics.

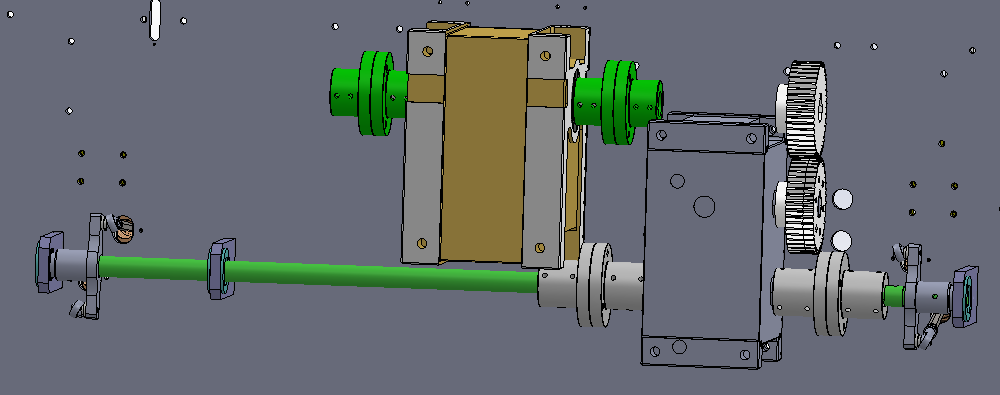

Spindle improvements: A. The reducer is changed to be directly connected to the motor to reduce vibration and noise.

B. The main shaft bearing is changed to a square seat bearing to increase strength and stability.

C. All cams are changed to disc groove cams and the tension spring accessories are removed. Increase cam stability while reducing machine failures caused by tension spring breakage. Reduce machine maintenance work.

After the above adjustments, the running speed of Boevan Horizontal Duplex Premade Pouch Packing Machine(BHP-210D) has been significantly improved, and it runs smoothly, the waste bag rate has been significantly reduced, the feeding accuracy has also been greatly improved, and the waste of materials has been reduced.

Post time: Sep-29-2024