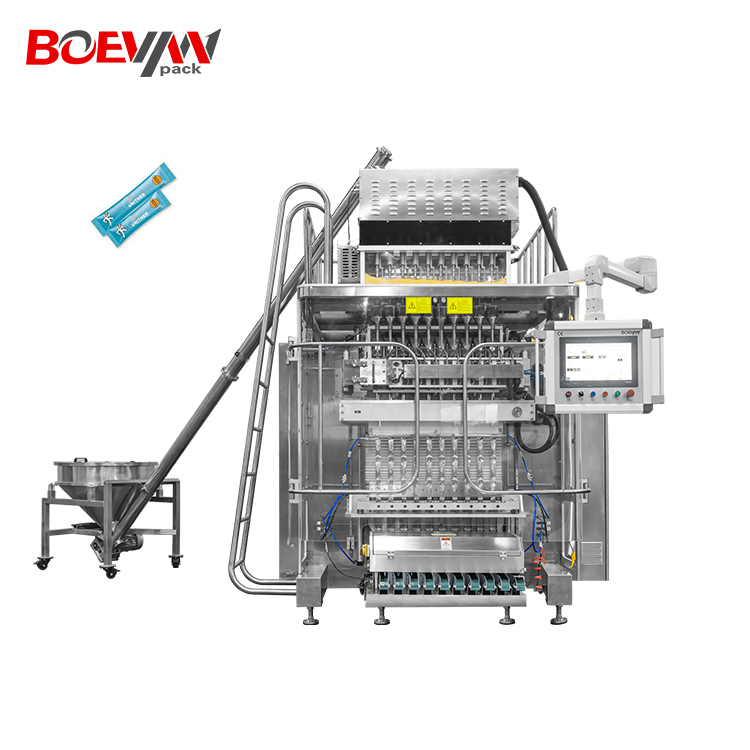

1.Appearance

1.1The frame is made of stainless steel and is made of thick material (the thickness of the machine board is 20mm). The appearance of the host is beautiful and grand, and it complies with European and American export standards.

2.Technology

2.1Use Schneider PLC, servo motors, drives, and touch screens; (the electrical components are all from well-known brands and can also be configured according to customer requirements)

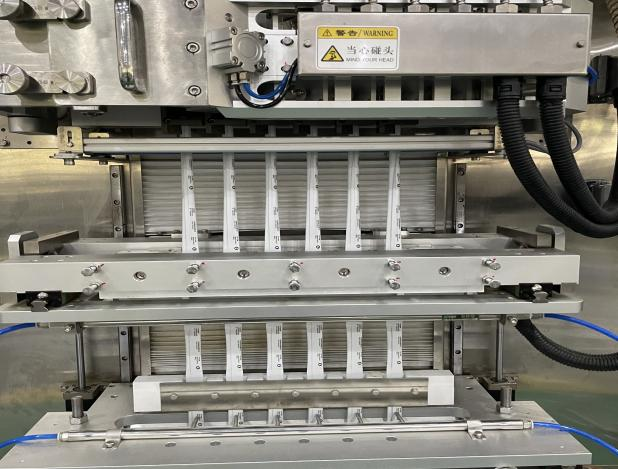

2.2Oblique vertical sealing, the sealing block will not directly contact the forming tube during the sealing operation, and the material will not be affected by heat when encountering high-temperature deterioration products; the vertical sealing block will pop up after shutdown, away from the forming tube, and will not be in production state down, causing unnecessary damage to the membrane and seal;

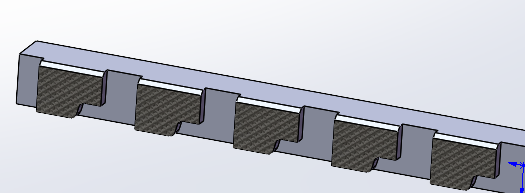

2.3The sealing block is produced using CNC finishing technology. The packaging seal is beautiful and the sealing strength is high; the horizontal sealing adopts a single power and dual drive mode (the front and rear sealing blocks can achieve dual control); the horizontal sealing block is made one soft and one hard to prevent the film from being damaged. Puncture and material leakage; two rows are controlled by one temperature control system, which facilitates maintenance and adjustment to avoid affecting production efficiency.

2.4 Powder materials can be equipped with a static elimination device to prevent powder from blowing back when unloading, affecting the sealing fastness and aesthetics;

2.5 This model of high-speed multi-row strip packaging machine has a speed of up to 50 cuts/row/minute; the nitrogen filling function can be added according to actual needs, and the residual oxygen content is less than 3%;

Post time: Aug-23-2024