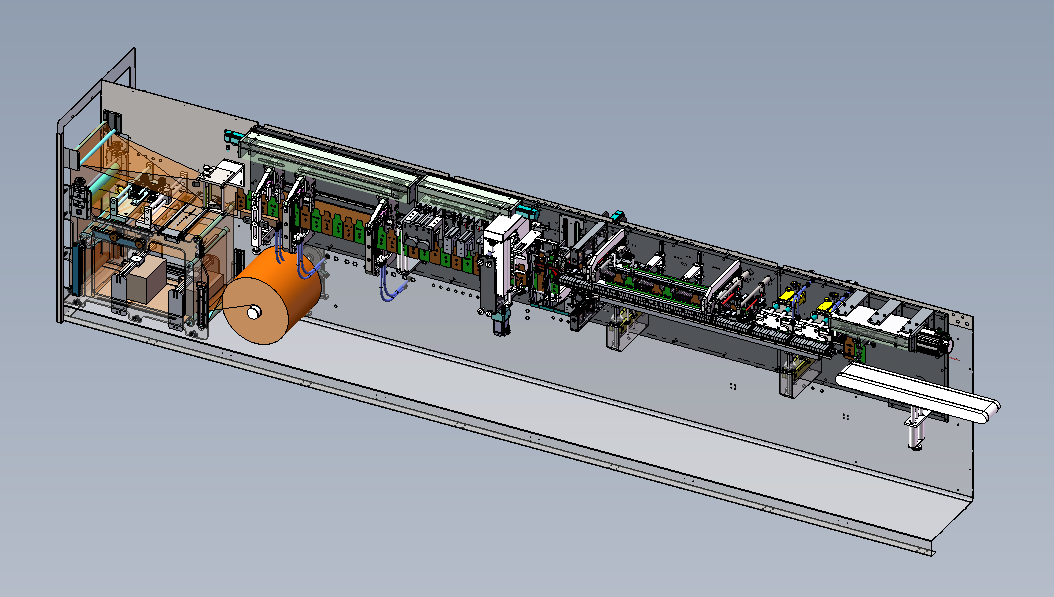

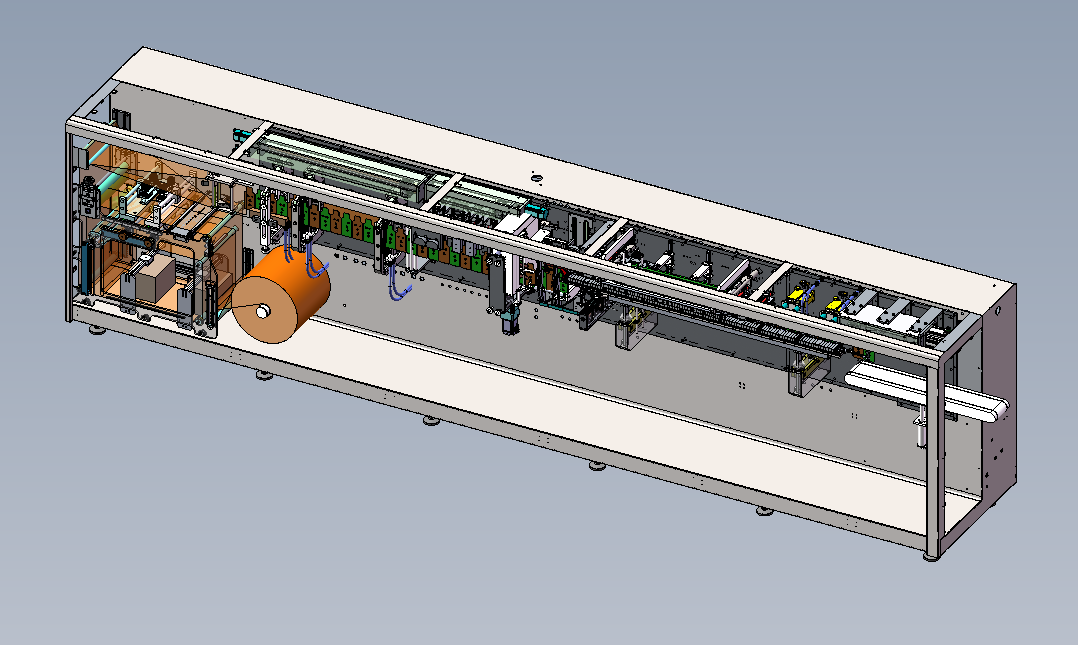

BHD-240DS OF Benefit Analysis

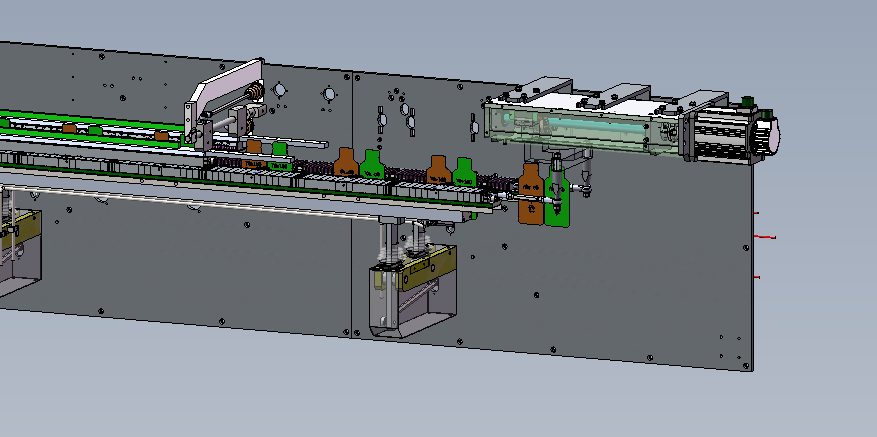

1.When the bag width of the original horizontal machine was changed, many places needed to be adjusted manually, which was very inconvenient, inefficient and inaccurate. The market needs a machine that can adjust automatically. As long as a few parameters are entered, the machine will automatically adjust. We designed this machine based on market demand.

90% of the adjustment work of the horizontal machine to change the bag width is concentrated in the left and right bag width directions, so we focus on solving this contradiction. After the customer enters the bag width, the equipment will automatically adjust the width.

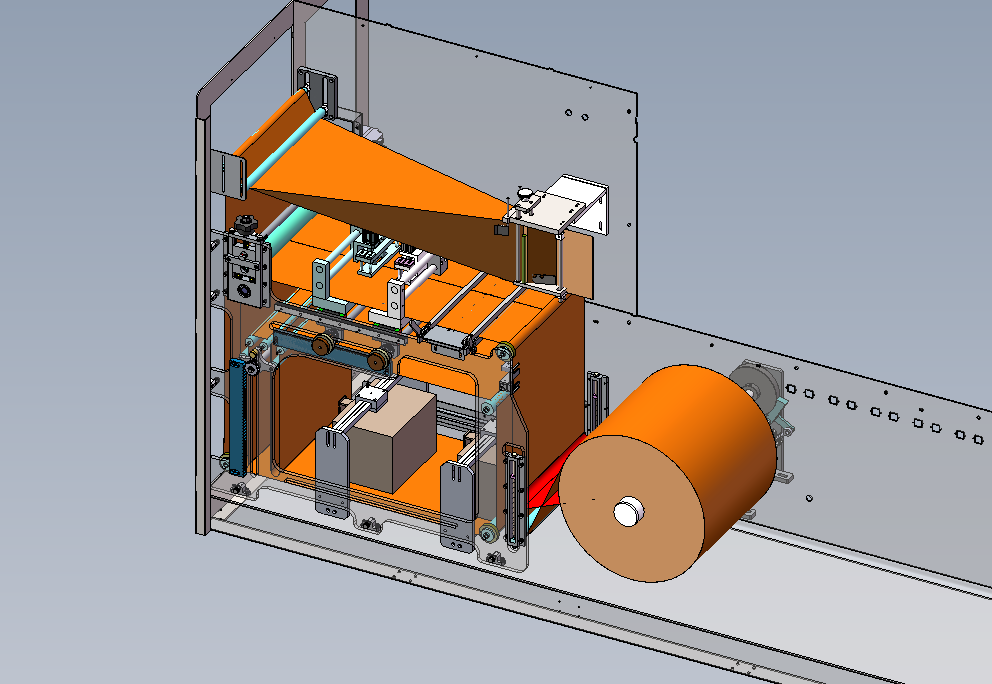

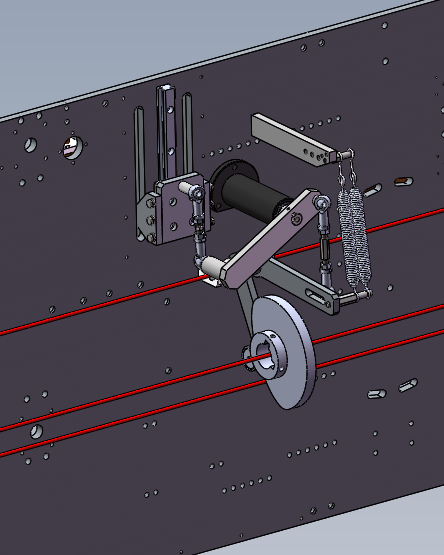

2.Servo film release

There are two types of film placing mechanisms for horizontal machines. One is a structure for making flat bags, which is inside the frame, and the other is a structure for making large bags and separated from the frame. Small self-supporting bags are very popular now. We need to realize the self-supporting bag function inside the frame. In such a small space, we also need to realize functions such as printing, film splicing, bottom punching, and film storage. Bottom punching requires relatively high precision, so we use servo motors to pull the film to make the stop accurate and improve the punching accuracy.

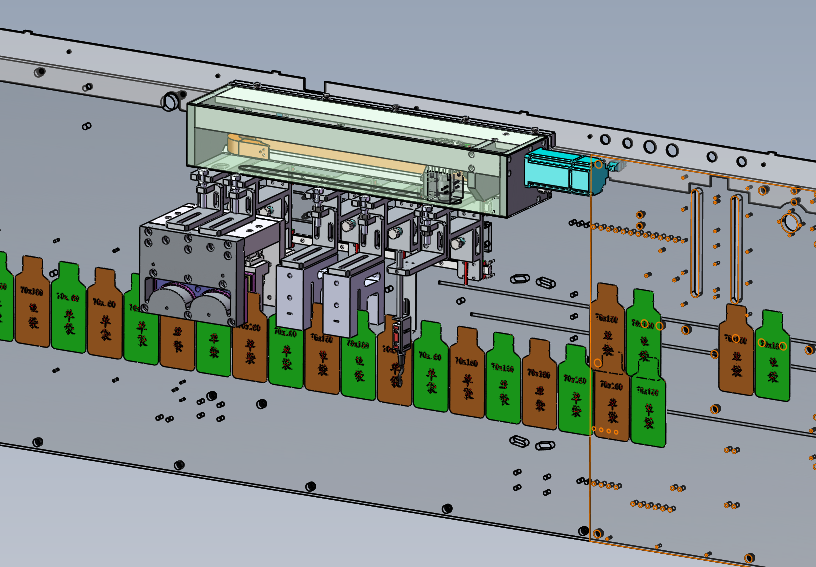

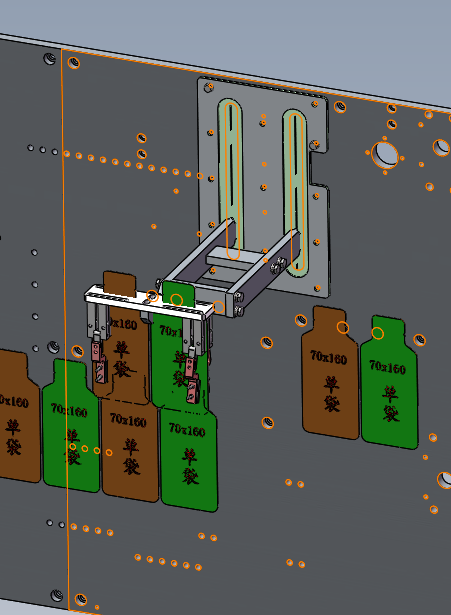

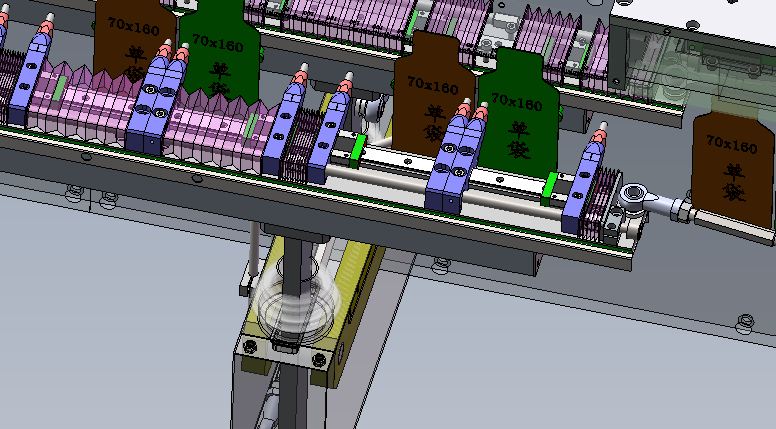

3.Sealing block servo adjustment position

The design basis of the entire double-outlet bag machine is the shearing station, because at this position, the front bag is connected, and the back bag is cut. The center position of the two bags at the shearing station will never change, regardless of the size of the bag. Then we can use this position as a reference to calculate the sealing block position of each bag width in advance and store it in the PLC. When switching bag types, you only need to enter the bag type to call out the data, and the sealing block will automatically move to the designed position.

4.Automatically search for color marks (change the bag width later to automatically search for color marks)

5.Bag lifting mechanism (more stable for making special-shaped bags)

6.Servo bag conveying device (more stable operation)

7.Front claw adjustment mechanism (easy to adjust bag width when changing bags, one adjustment to change bag width)

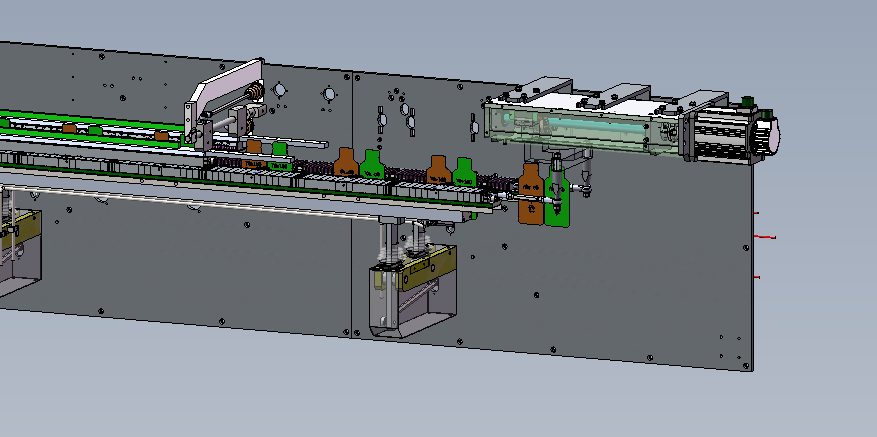

8.Servo spindle

Make the equipment run more stably.

Post time: Sep-20-2024