BVS6-680 Vertical Multi-lanes Stick Bag Packing Machine

Our equipment racks are made of stainless steel stamping parts and are made of thick materials (stainless steel material thickness 1.5). The main machine has a beautiful appearance and meets European and American export standards.

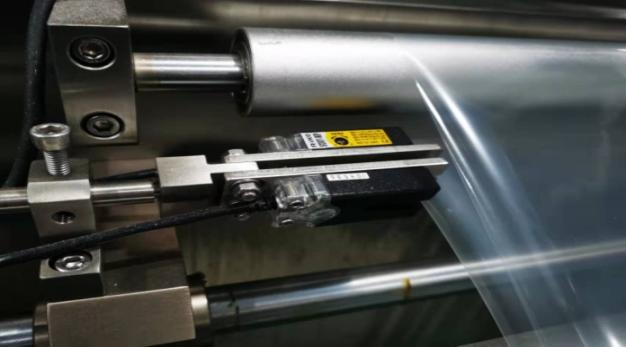

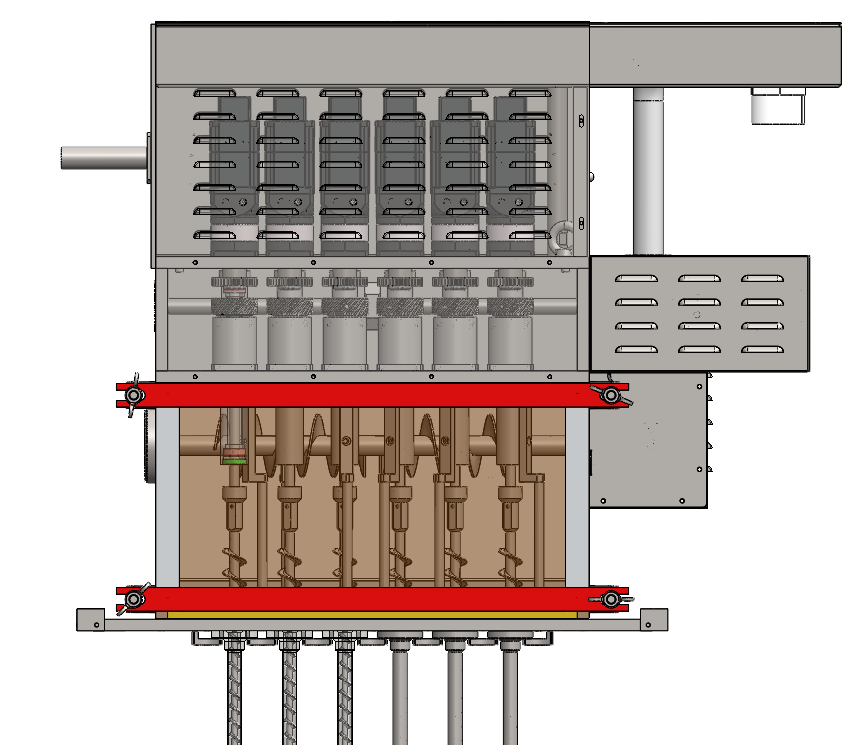

The longitudinal sealing adopts the most advanced water-cooling system in the packaging industry to ensure that the material does not produce high-temperature bacterial changes during the filling process;

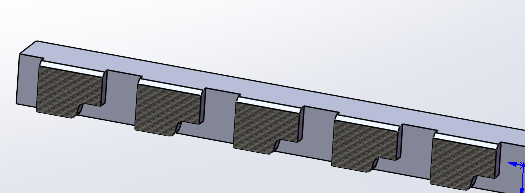

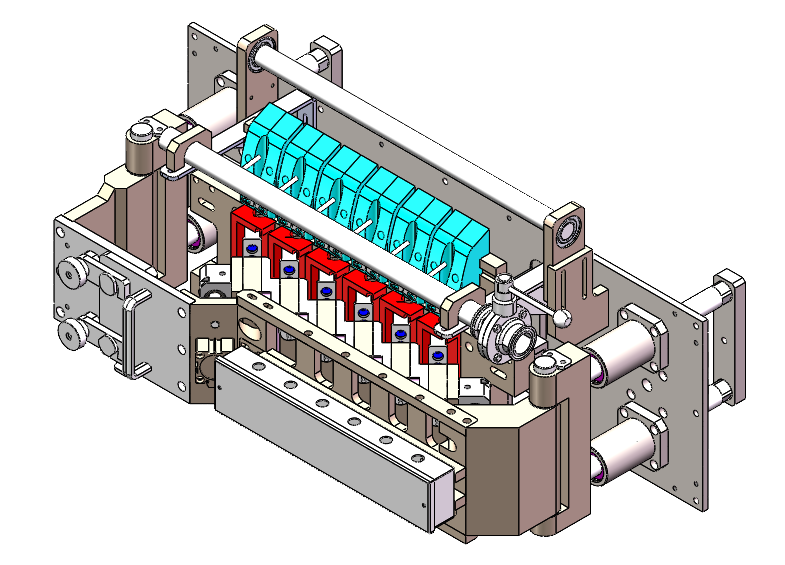

The sealing block adopts CNC finishing technology, the packaging seal is beautiful and the sealing strength is high;

The film running adopts automatic deviation correction technology to ensure that the film does not deviate and the longitudinal seal is beautiful;

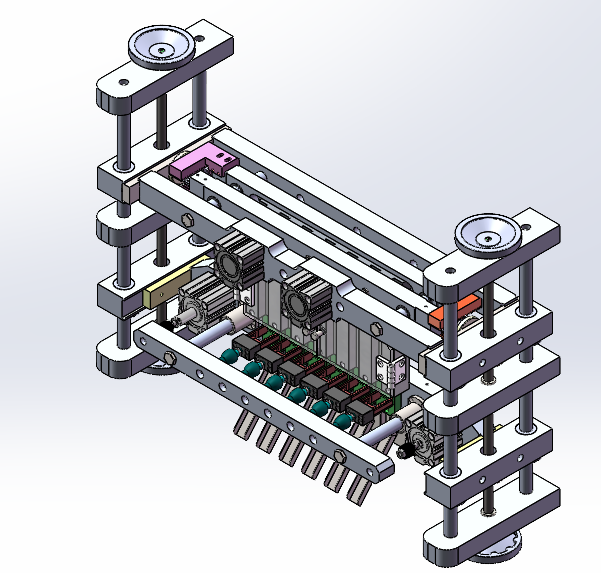

All parts in contact with the material are modular and quick-disassembly designed. The metering parts can be pulled out as a whole and disassembled quickly. It can be disassembled in 15 minutes, making it easier to change batches, clear the site, and switch specifications;

We can quickly help customers analyze material characteristics, help customers determine whether the original measurement method of new materials is suitable, or help customers redesign and quickly verify speed and accuracy;

Boevan has a variety of screw solutions based on different material characteristics and parameters to ensure reasonable compression and reliable precision, and will not affect production operations due to material blockage or damage to the screw;

It adopts a multi-channel dust removal structure, and cooperates with the workers to start the dust removal at the same time as cutting and sealing according to the cutting sequence, further ensuring the sealing quality and production stability;

All parts are marked, which facilitates quick confirmation of part drawing numbers and reduces search time and error rate;

The entire line is equipped with a remote control module to conduct online diagnosis of the equipment and software system upgrades with the customer's permission;

Screw metering enables material pressure control, customized screw design, and reduces extrusion and crushing of materials. Filling of different materials can be achieved by simply replacing the screw.

After-sales

Boevan Company has an independent after-sales department and a professional after-sales team. We will respond to equipment installation, debugging and after-sales issues as soon as possible. The equipment has a one-year warranty and lifetime paid maintenance.

Post time: May-22-2024